Expert FEA, CAD, and CFD

Services for Every Industry

Simulation-driven engineering solutions across aerospace, automotive, energy, and more – delivering cost savings and faster time-to-market.

What We Do

- Linear and non-linear analysis

- User Subroutine

- Composite modelling

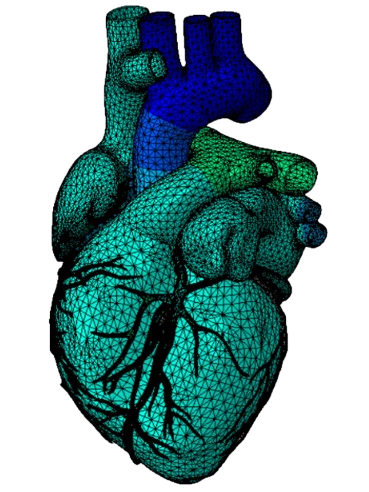

- Biomedical application

- Structural modelling

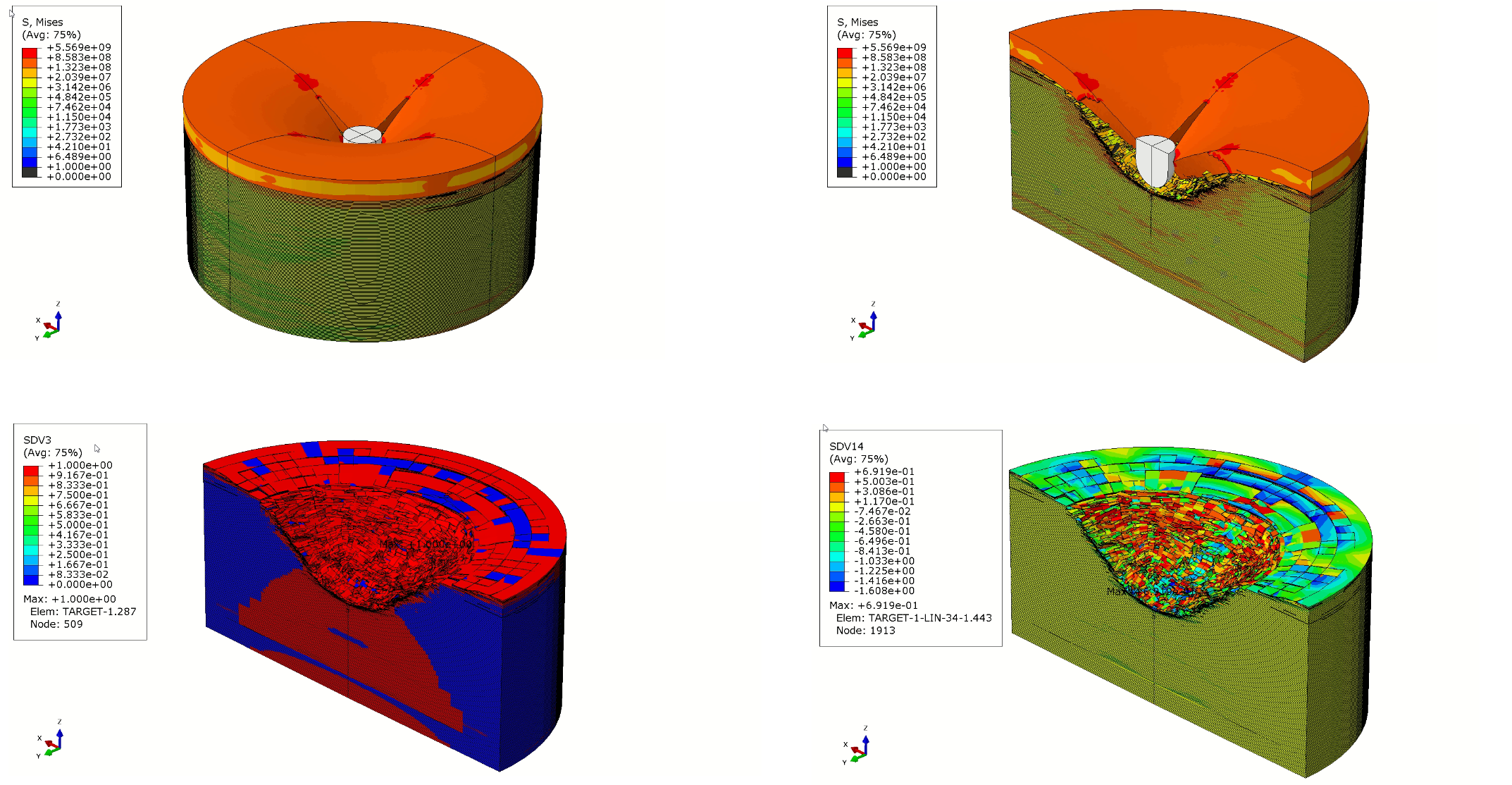

- Geotechnical Application

- Additive Manufacturing

- Welding analysis

- Piezoelectric Modelling

- Polymer analysis

- Machining operation

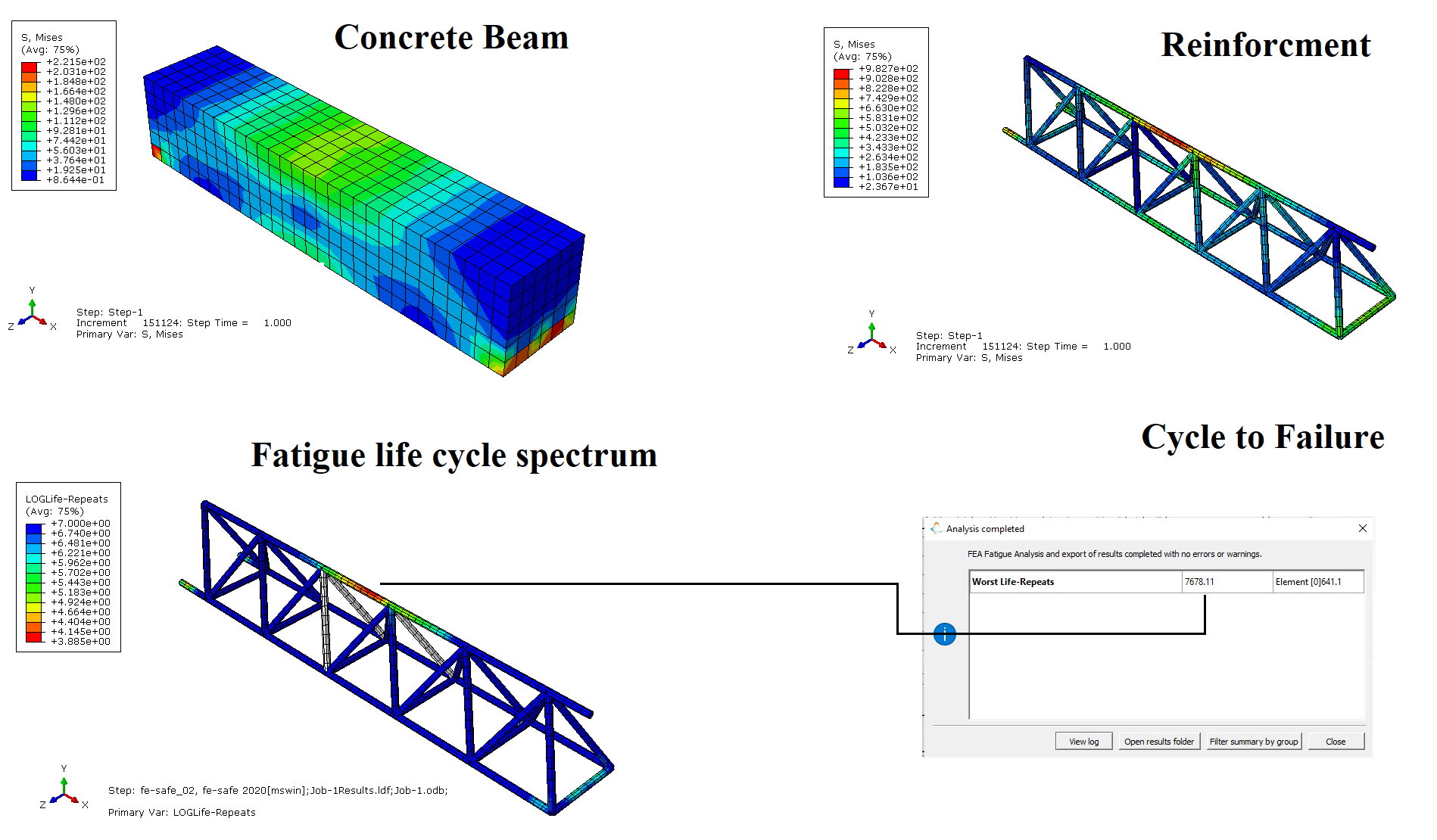

- Concrete analysis

- Heat transfer analysis

- Low cycle fatigue assessment

- High cycle Fatigue modelling

- Uni-axial stress based approach

- S-N curve prediction

- Multi-axial stress life approach

- Low cycle Fatigue modelling

- Uni-axial strain based approach

- Multi-axial strain life approach

- Mean stress correction

- Weibull distribution factor

- Fatigue failure Probability

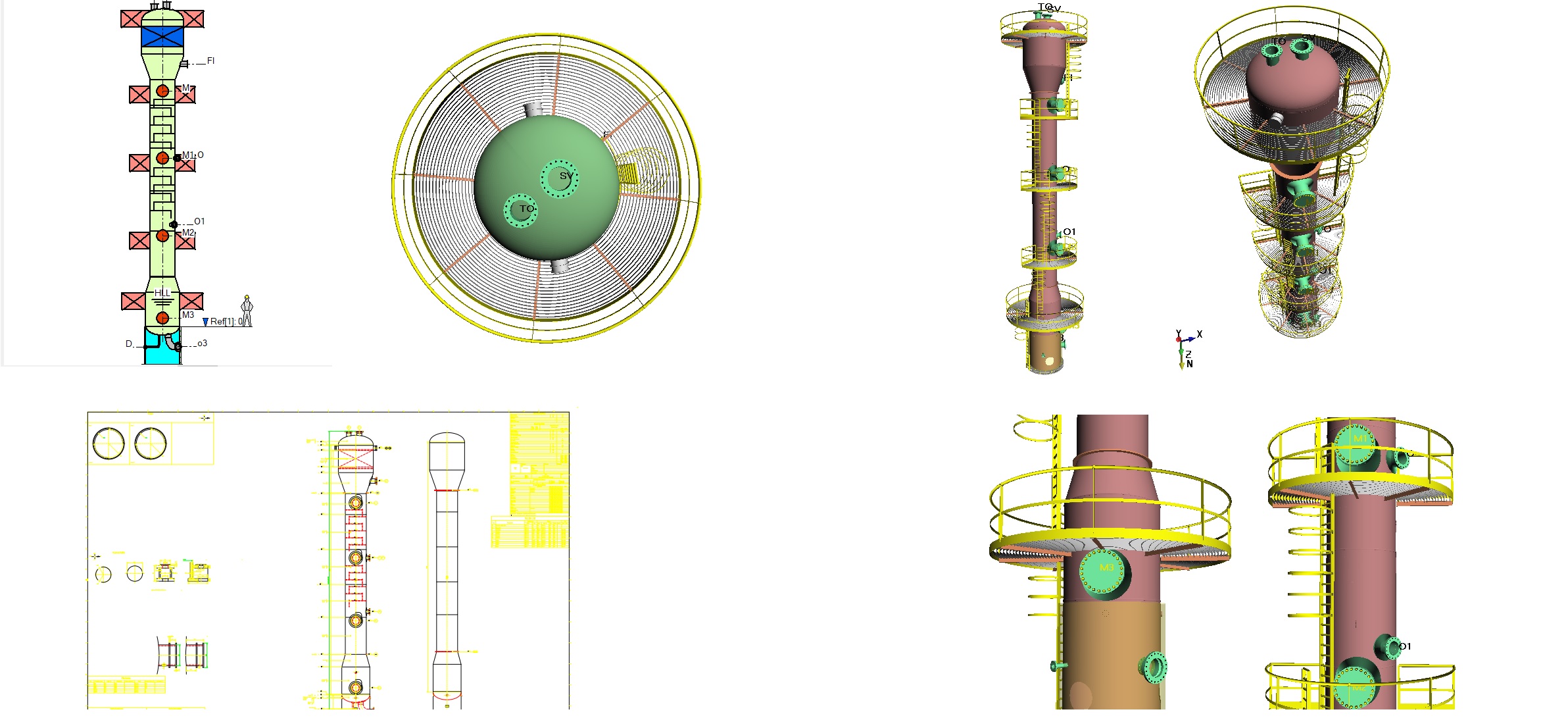

- Design of fluid storage tank

- Saddle and Skirt support vessels

- Thermo-mechanical analysis

- Spherical Pressure vessel design

- Vacuum filter design

- Multi-chambered pressure vessels

- Long distance pipelines

- Pipeline safe -span modelling

- Bills of material

- Generating Engineering design

- Vertical leg supported vessels

Project Showcase

Take a look at our featured projects

-

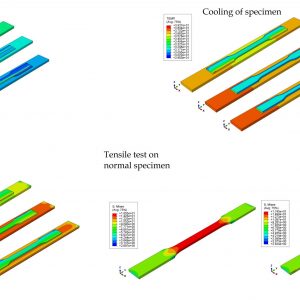

Modeling of Isothermal Deformation in Metals and Alloys Using Strain-Compensated Arrhenius Models via VUHARD Subroutine in ABAQUS (Gleeble Thermo-Mechanical Simulator

$ 500 -

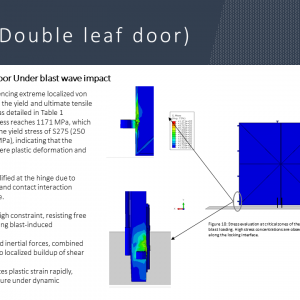

Evaluation of Structural Behavior of Steel Doors and its component Subjected to Air Blast Loading

$ 300 -

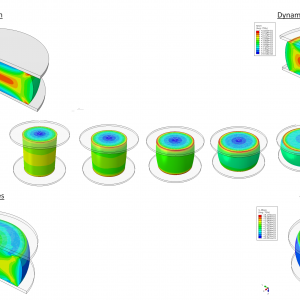

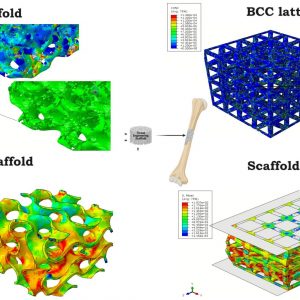

Digital Healing: Numerical Simulation of 3D Printed Magnesium Bone Scaffolds for Regeneration via LDED Printing Technology

$ 300 -

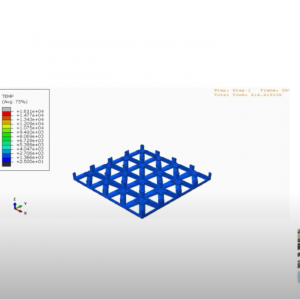

Assessing Fatigue Life of 3D Printed Biodegradable PLA Specimen vs Standard PLA Specimen

$ 300 -

Additive Manufacturing of Airless Tyres Using Viscoelastic Model Based on Polymer Extrusion Technique

$ 300 -

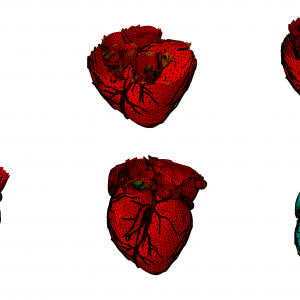

3D Bio-Printing of Full Size Model of Humun Heart

$ 300 -

Comparative Analysis of MG “Magnesium” Scaffold Shapes: Modelling Corrosion and Mechanical Resilience in Simulated Body Fluids

$ 250 -

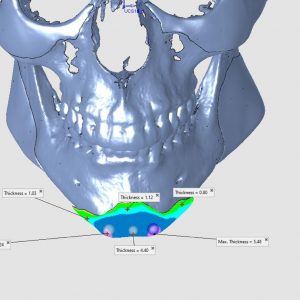

Chin, Cheek, and Jaw Reshaping: Using FEA Approach in Facial Enhancement for Biomedical Application

$ 250

Who We Are

We are a team of highly skilled and meticulous Mechanical Design Engineers with vast experience in the analysis and design of complex engineering environments. Our expertise lies in computer-aided engineering, specifically in finite element modeling and analysis, fatigue life assessment, and thermo-mechanical structure assessment. We are also experienced in the design and analysis of pressure vessels and long-distance pipelines.

Throughout our careers, we have demonstrated a proven ability to apply CAE skills to evaluate component/process performance, resulting in improved efficiency and reduced costs. As team players with strong time management skills, we are able to work effectively in cross-functional areas.

We are proficient in various software, including ABAQUS, Fe-safe, XFLOW, TOSCA, Auto-PIPE, Auto-Vessel, AutoCAD, Pro/ENGINEER, Creo, ReplicatorG, ANSYS, SOLIDWORKS, and LabVIEW, among others.

We are passionate about using our skills and expertise to drive results and deliver value. With a keen eye for detail and a commitment to excellence, we are always eager to take on new challenges and exceed expectations.

Thank you for visiting our website, and please feel free to explore our portfolio to learn more about our professional projects and accomplishments. We looking forward to work with you.