Additive Manufacturing of Airless Tyres Using Viscoelastic Model Based on Polymer Extrusion Technique

$ 300

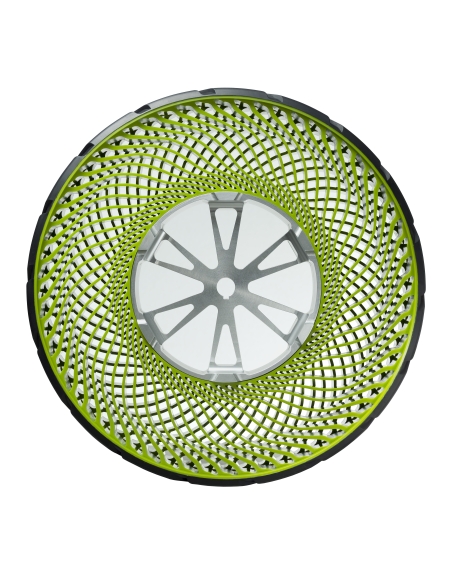

In FEA basic aim of 3d printing simulation is to predict thhe excessive distortion and residual stresses during rapid heating and cooling of the part during printing. The airless design taken in this study is from Bridgestone tyres. This airless tire technology features a unique spoke structure designed to support the weight of a vehicle, effectively eliminating the need to periodically refill the tires with air.

Additive Manufacturing (AM) is an appropriate name to

describe the technologies that build 3D objects by adding

layer-upon-layer of material. In this simulati0n progressive material addition based on polymer extrusion technique is used to deposit layer of material. In Polymer extrusion technique an extruder puts down molten beads on top of a previous layer and as they solidify, they fuse to the

existing part

Abaqus Modelling

A coupled thermo-mechanical simulation is performed in abaqus using Polyurea as a base material. First, a heat transfer analysis is performed on the part with appropriate and specific temperature boundary conditions and flux loads (laser) Once the heat transfer analysis is complete, the temperature profiles are used to drive a static analysis of the part to predict distortions. Position and time of the laser is specified by entreing event series data that comes from the NC codes generated by convential softwares Replicator/creo-CAM. Also from the stres analysis of the tyre for the exisitng material model it was observed that these tyres can easy withstand load of 700-1000kg with deformed excessively.

Access to Original Files

Our packages include comprehensive design documentation, detailed analysis reports, and essential files, all readily available for download. This collection ensures that you have everything needed to replicate the project or adapt it to fit your specific needs.

Project Customization

If you’d like to improve or modify our featured project to better suit your requirements, we offer customization services. This includes adjusting design parameters, adding extra analyses, or creating variations tailored to your industry or application.

Tutoring & Consultation

Receive expert guidance on complex engineering concepts through comprehensive tutorials and live sessions, designed to help you understand and apply these subjects effectively. Our expert-led tutorials provide a clear, step-by-step guide to complex engineering concepts.