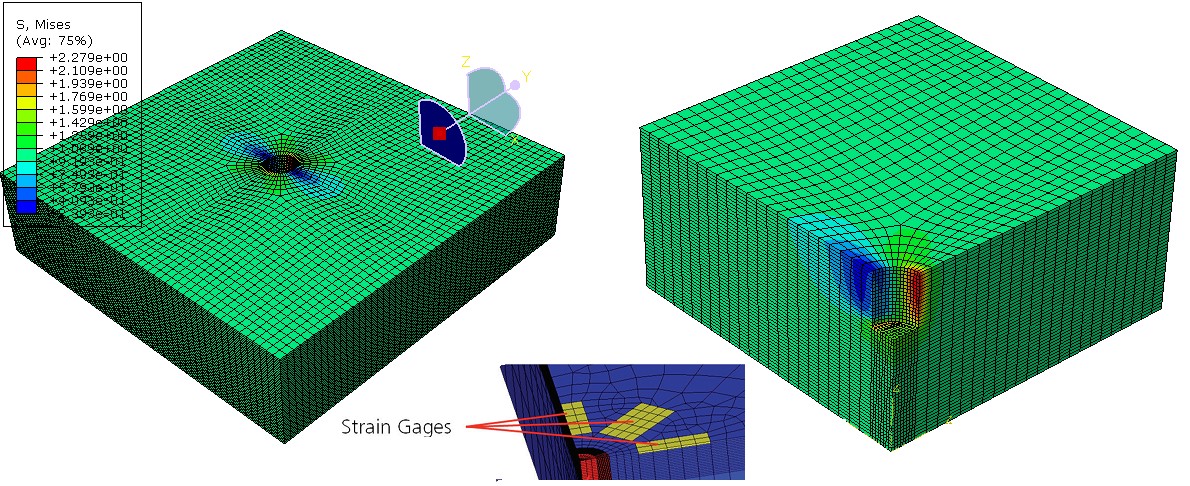

Incremental hole drilling is widely used technique to measure the surface residual stresses due to its high precision and being economic. In Incremental hole drilling process, a rosette is installed having capability of measuring multi directional strain, a hole is drilled in the center through a successive increments and surface stress stresses are monitored. This incremental hole drilling methodology converts the relaxed strain induced by the hole drilling into a sub-surface stresses which is the measured by the installed rosette gauge. Experimentally at the position of the hole drilling, a rosette with 3 different gauges arranged at 00, 450 and 90. Stress maximum when the angle of applied load is parallel to direction of stress measurement. While it is found to be almost negligible for the other 2 orientations

Access to Original Files

Our packages include comprehensive design documentation, detailed analysis reports, and essential files, all readily available for download. This collection ensures that you have everything needed to replicate the project or adapt it to fit your specific needs.

Project Customization

If you’d like to improve or modify our featured project to better suit your requirements, we offer customization services. This includes adjusting design parameters, adding extra analyses, or creating variations tailored to your industry or application.

Tutoring & Consultation

Receive expert guidance on complex engineering concepts through comprehensive tutorials and live sessions, designed to help you understand and apply these subjects effectively. Our expert-led tutorials provide a clear, step-by-step guide to complex engineering concepts.