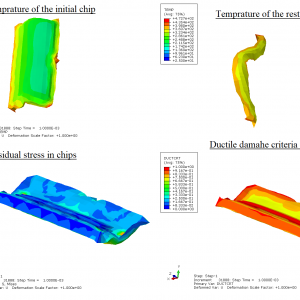

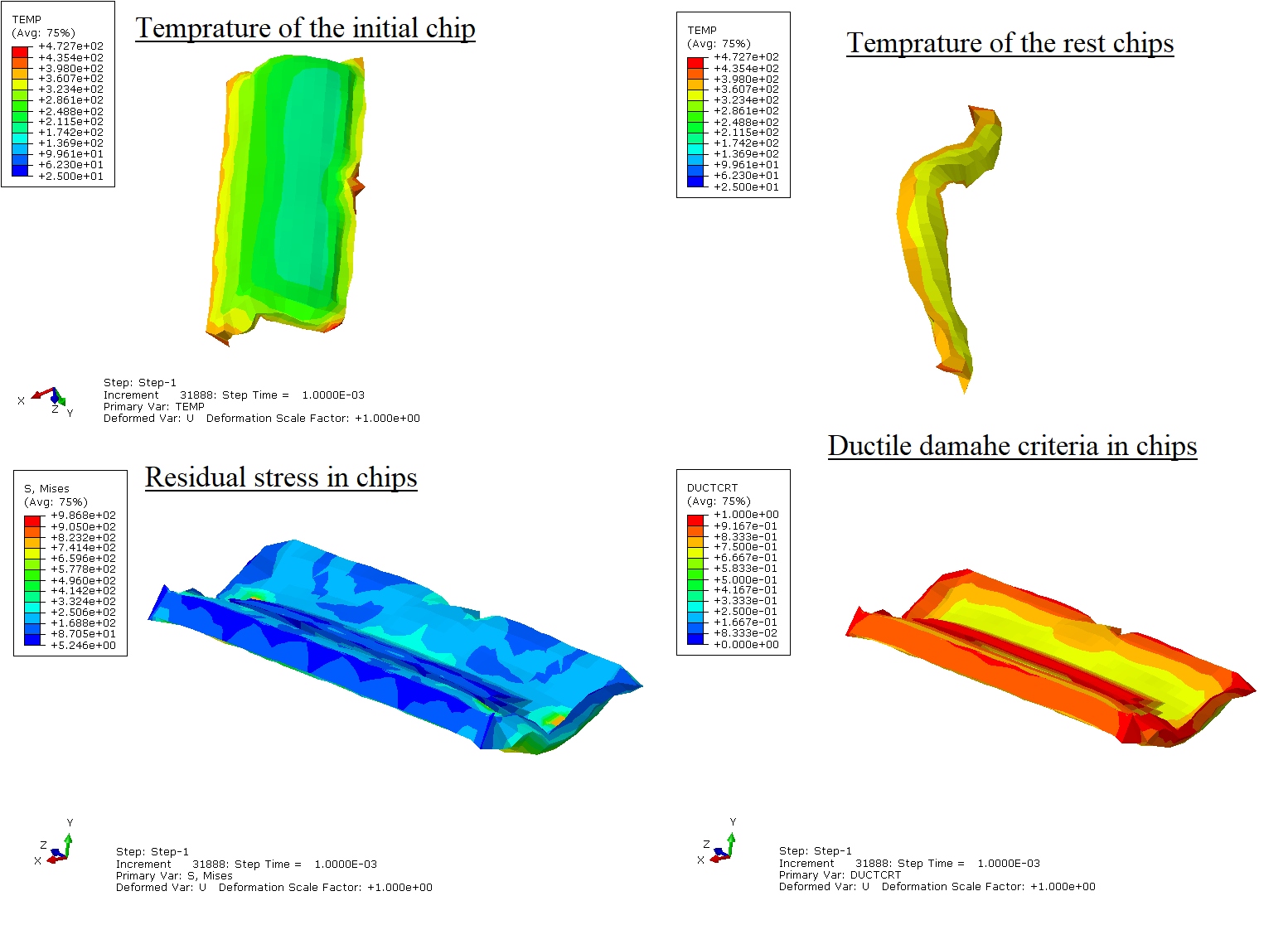

The total length of the specimen is 100 mm. Cumulative damage model which includes Ductile damage criteria alongside damage evolution, shear damage criteria are used to predict the damage initiation. While Johnson cook parameters are used to model its plastic behavior with damage evolution. Solution dependent variables were taken as unity. Temperature DOF were allowed at the integration points using Dynamic temperature explicit step. Formation of the chips strongly influence by the rotation speed of the tool. For the interaction the drill surface is connected with the nodes of the work piece using kinematic contact using thermal gap conductance, heat generation, and penalty as interaction property. The tool surface is coupled at the center while defining the COR at a same point while defining rigid constraint.

Access to Original Files

Our packages include comprehensive design documentation, detailed analysis reports, and essential files, all readily available for download. This collection ensures that you have everything needed to replicate the project or adapt it to fit your specific needs.

Project Customization

If you’d like to improve or modify our featured project to better suit your requirements, we offer customization services. This includes adjusting design parameters, adding extra analyses, or creating variations tailored to your industry or application.

Tutoring & Consultation

Receive expert guidance on complex engineering concepts through comprehensive tutorials and live sessions, designed to help you understand and apply these subjects effectively. Our expert-led tutorials provide a clear, step-by-step guide to complex engineering concepts.